Safety

It is the policy of SKINNER INTERIOR SYSTEMS, INC. to carry out a thorough program of accident investigation. Supervisory personnel will be primarily responsible for making an investigation of all accidents in their areas of responsibility. Accidents involving fire, death, serious injury, or extensive property damage will be investigated jointly by the Supervisor and the Owner.

The primary goal of the accident investigation program is the prevention of future similar accidents through the use knowledge derived from the investigations. Additionally, the investigation will be used to prepare reports required Federal and State law as well as the Worker's Compensation Insurance Carrier. These Reports are critical in establishing the Company and Supervisor's liability under the law.

When an employee in injured at work, the supervisor is responsible for taking emergency action to have first aid administered to obtain professional medical attention as soon as possible and protect other employees and equipment. The supervisor must then begin to investigate the circumstances of the accident. The following procedures have been found to be effective when investigating accidents:

- Go to the accident scene at once.

- Talk with the injured person, if possible. Talk to witnesses. Stress getting the facts, not placing blame or responsibility. Ask open-ended questions.

- Listen for clues in the conversations around you. Unsolicited comments often have merit.

- Encourage people to give their ideas for preventing a similar accident.

- Study possible causes - unsafe conditions, unsafe practices.

- Confer with interested person about possible solutions.

- Write your accident report giving complete, accurate account of the accident.

- Follow up to make sure conditions are corrected. If they cannot be corrected immediately, report this to your supervisor.

- Publicize corrective action take so that all may benefit from the experience.

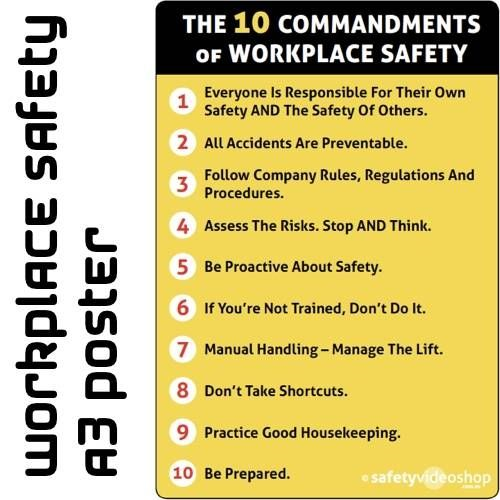

For the protection and safety of all employees, SKINNER INTERIOR SYSTEMS, INC. has established the following rules designed to prevent accidents and injuries. Compliance with these rules is mandatory for all personnel.

1. Proper footwear and clothing will be worn at work at all times.

2. Horseplay, running fighting or any activity that may result in injury or waste will not be tolerated.

3. Eye protection is required when performing any task and could produce flying particles.

4. Operate all machinery with guards in place. Tampering with safety devices is cause for immediate disciplinary action, up to and including termination.

5. Do not operate any equipment that you are not familiar with.

6. Machines must never be cleaned adjusted or repaired until after the machine is turned off, the circuit is broken at the source and a warning tag is placed at the controls. Each person involved in maintenance must have his/her own personal padlock to ensure total lack of power until all work has been completed.

7. Any defects in material, machinery, tools and equipment must be reported immediately to a supervisor.

8. Do not leave tools, materials or other objects on the floor, which might cause others to trip and fall.

9. Avoid risk of rupture, internal injury or back injury in attempting to lift or push excessive loads. If an object is too heavy to move without strain, ask for help.

10.Observe the correct position for lifting. Stand with your feet slight apart, assume a squatting position with knee bent and tuck your chin. Tilt head forward, grasp the load with both hands and gradually push up with legs, keeping your back straight and avoiding any abrupt movement.

11. Do not distract others while working. When approaching a machine or forklift operator for any purpose, do so from the front or side in a way that he or she will see you coming and will not be shocked or surprised. If conversations necessary, first make sure the machine is turned off.

12. Do not allow oil, water, or any other material to remain on the floor where you or others may slip. Report any spills to your supervisor.

13. When handling hazardous materials insure you follow prescribed safety procedures and use required safety equipment. When using secondary containers filled by others, insure that they are libeled as to their contents and hazards.

14. Use appropriate gloves when handling materials with shaper or jagged edges, which might result in lacerations.

15. Do not attempt to operate machinery for which you are not trained.

16. Unnecessary and excessive haste is the cause of many accidents. Exercise caution at all times WALK, DO NOT RUN!

17. The use of hot production equipment or materials for the purpose of cooking or heating food is strictly prohibited.

18. All work related injuries and accidents, no matter how minor, must be reported immediately to your supervisor.

19. If you have any questions and/or concerns about the safety of any operations, do not hesitate to discuss it with your supervisor immediately.

It is imperative that all employees become thoroughly familiar with the above safety rules. Failure to comply with safety rules or procedures, or failure to wear the appropriate safety equipment, will result in disciplinary action up to and including termination.

Under the new provisions of the standard, the Project Manager will be required to perform work place hazard assessment to determine the presence of hazards that necessitates the use of PPE. The developer then selects appropriate equipment to protect employees from those hazards. In addition, the developer will educate and train all affected employees in the proper use and maintenance of PPE. Each such employee shall be trained to know at least the following:

- When PPE is necessary

- What PPE is necessary?

- How to properly don, doff, adjust and wear PPE

- The limitations of PPE

- The proper care, maintenance, useful life and disposal of the PPE

- It is necessary to remember, that PPE devices alone should not be relied on to provide protection against hazards, but should be used in conjunction with safeguards, engineering controls, sound operating practices, discipline and common sense.

Each affected employee shall use appropriate (ANSI Z87.1-1989) eye or face protection when exposed to eye or face hazards from flying particles, molten metal, liquid chemicals, acid or caustic liquids, chemical gases or vapors or potentially injurious light radiation. (Consult MSDS for chemical eye protection requirements).

Eye protection that provides side protection shall be used when there is a hazard from flying objects or particles.

Each affected employee who wears prescription lenses shall wear eye protection that incorporates prescription in its design, or shall wear eye protection that can be worn over the prescription lenses without disturbing the proper position of prescription lenses or the protective lenses.

Each affected employee shall use filter lenses that have a shade number appropriate for protection from injurious light radiation (see table at the end of this section). Safety Glasses Must Be Worn at all times When Using A Saw, Grinder, Router, Cutting Torch Or Powder Actuated Tools.

Each affected employee shall wear protective helmets when working in the areas where there is a potential for injury to the head from falling objects or low overhead clearances.

Employees working near exposed electrical conductors should wear protective helmets designed to reduce electrical shock hazard. Hard Hats Must Be Worn At All Times.

Protective helmets purchased after July 5, 1994 shall comply with ANSI Z89.1-1986.

Each affected employee shall wear protective footwear when working in areas where there is a danger of foot injuries due to falling or rolling objects, or objects piercing the sole, and where employee’s feet are exposed to electrical hazards. Safety Boots Must Be Worn At All Times.

Protective footwear purchased after July 5, 1994 shall comply with ANSI Z41-1991.

The Contractor shall select and require employees to use appropriate hand protection when employees’ hands are exposed to hazards such as those from skin absorption of harmful substances (consult MSDS), severe cuts and lacerations, abrasions, punctures, chemical or thermal burns and harmful temperature extremes.

Any employee exposed to fall hazards of 6 feet or more who is not protected by a handrail must use an approved safety harness/belt, lanyard or lifeline, horizontal lines, catenary lines, or other approved means of protection unless covered by the OSHA Steel Erection Standard (29CFR1926 Sub part R). Approval should come from the project superintendent.

Employees must use positive fall restraint or fall arrest at all times where employees are working at heights greater than 6 feet. Situations where fall restraint or fall arrest is necessary include, but are not limited to:

Before any employee begins work on a project that requires the use of scaffolding--a temporary elevated platform and supporting structure designed to support workers and their materials--he/she should be thoroughly familiar with the various types of scaffolding and work rules

The first and easiest rule to remember about scaffolding is:

- Every day, inspect the scaffold thoroughly for damage or wear before an employee begins to work on it.

- Do not climb to the platform on bracing or frames not designed for climbing.

- Use both hands and face the rungs going up or down.

- Do not carry any materials when climbing.

- Do not let hands go until good footing is established and platform access is available.

- Keep one hand firmly on the frame or ladder at all times.

- Do not work on slippery platform.

- Do not overload work platforms with materials.

- Never remove any component of a completed scaffold, except when directed by a supervisor. If a component is removed, replace it immediately

- If there are overhead hazards, provide overhead protection.

- Wire, synthetic, or fiber rope used for scaffold suspension must be able to support at least six times the intended load.

- Clean your shoes free of grease, dirt, or debris before climbing.

- Both supervisors and employees must always inspect all scaffold components each day they begin work. Immediately report hazardous conditions.

- To get the scaffold, use the designated safe access. If no safe access has been provided, report this condition immediately to your supervisor.

The general scaffold work rules above also apply to rolling scaffolds. In addition, the following rules must be carefully observed:

- Employees must never ride a manually propelled rolling scaffold while it is being moved.

- Do not construct a bridge between rolling scaffold towers with planks or stages.

- While working, do not lean over scaffold guardrails to extend your working area.

- Secure all materials on scaffold before moving it.

- Before an employee moves a scaffold, he/she must make sure the floor surface is clear of all obstacles, obstructions and holes. Move all electrical cords. Employees should also keep their eyes open for potential overhead obstacles.

- Never move rolling scaffolds by pulling the top section.

- Always move by pushing the scaffold base.

- Use rolling scaffolds only on a level base.

- Inspect ground conditions for the strength of the supporting structure. Frame spacing and mudsill size can be assessed only after the total weight the scaffold will hold and the strength of the supporting soil or structure is determined by a supervisor or qualified person.

- The scaffold’s footings or anchorage should be sound and rigid, capable of carrying the maximum intended load without settling or displacement.

- Look at the overhead obstructions, such as electric power lines or other obstacles. Do not erect any scaffold without first determining if the working conditions require overhead protection. If required, install or put it in place before erecting the scaffold.

- Consider on-site weather conditions, such as wind, rain or snow. Provide weather protection where weather will influence the safety of employees working on the scaffold

- A stationary or fixed scaffold should be no more than 125 feet in height. If the stationary scaffold needs to be higher, a professional engineer must design it

- A portable or rolling scaffold should be no more than 60 feet in height. If the portable scaffold needs to be higher, a professional engineer must design it.

- Inspect wood planks to ensure it has been graded for scaffold use. Not all types and grades of lumber can be used for scaffolding. Wood should be sound, straight grained, with no splits, holes or saw cuts.

- If any scaffold or its components such as braces, brackets, trusses, screw legs, couplers, ladders, etc. is damaged or weakened in any way, it must be repaired or replaced immediately.

- The scaffold must be assembled under the supervision of a qualified person.

- The appropriate safety gear, including hardhat, must be worn at all times while erecting, moving, dismantling or using scaffolding.

Employees should take these additional precautions when erecting and using rolling scaffolds.

- The scaffold height must not exceed four times the minimum base dimension. Employees should use outrigger frames or outrigger units to increase the base width dimension when necessary.

- Casters must be secured to frame legs or screw jacks with a nut and bolt or similar fasteners. The weight of the tower cannot exceed the weight capacity of the casters.

- Screw jacks must not extend more than 12 inches above the caster base.

- The scaffold must be kept level and plumb at all times.

- Use horizontal/diagonal bracing on a rolling scaffold at the bottom and the top of the tower, and every 20 foot interval in between.

- Fabricated planks with hooks can replace the top diagonal brace. Cross-brace all rolling scaffold frames.

- On the platform, employees must use only prefabricated plank or cleated plank.

- Firmly lock all casters when the scaffold is not being moved.

- Do not use ropes, chains or slings that are defective.

- Do not overload cranes, ropes, blocks or chains.

- Do not ride loads.

- Control the load by use of a tag line.

- Stand clear of taut cables or hoists.

- Keep hands or fingers away from rope blocks and sheaves.

- Stay out from under overhead loads.

- Store materials securely, not in aisles or walkways. Do not stack materials too high and ensure that pipe, drums and other materials that may roll are properly blocked before a second layer is stacked.

- When storing material inside buildings under construction, do not place within 6 ft. of any hoist way or floor opening or within 10 ft. of an unfinished exterior wall.

- Fasten down loads securely before shipping. When unloading, be absolutely sure before the rigging is released and the strapping cut so that any material that may roll or fall is blocked, or otherwise safely supported by a lift truck or other mobile equipment.

- Always keep oily rags and flammable trash in covered metal containers.

In the construction industry, a back injury is the most common of all injuries. The injury is generally caused by the lack of knowledge of HOW to lift.

The following are recommended safe practices for lifting and carrying heavy objects. When a worker has to lift a heavy object and move it to another location, he/she should:

- Inspect the location for tripping hazards.

- Make sure the load is within your lifting capability. If not GET HELP!

- Set your feet solidly and well apart, with one foot slightly ahead of the other.

- Crouch as close to the load as possible, with the legs bent at about a 90 degree angle at the knee.

- Keep the back as straight as possible. It should not be arched.

- To lift the object, straighten your legs, keeping your back as straight as you can.

- Don’t twist or turn while lifting.

Common sense when using any tool or equipment can help reduce injuries.

Power activated and electric hand tools that are not used in the prescribed manner or are defective cause many eye and hand injuries. Preventive maintenance should be scheduled for all kinds of tools and/or equipment. Any individual should never use tools or equipment until he has been trained in the proper use, care and hazards of each tool and piece of equipment.

The following are recommended safety procedures and/or precautions in the use and care of power and hand tools:

- All tools should be kept in good repair, inspected daily and be ASA approved.

- Tools should be used only for that which they were designed.

- Defective or worn tools should be replaced.

- Tools should never be dropped from one level to another.

- Tools should not be left on scaffolds, platforms or other locations where a tripping or falling hazard is created.

- Inspect cords of electrical tools daily. Do not pull tools by the cords. Keep cords out of water, oil or chemicals.

- Keep sharp-edged tools sharp. Dull tools can be dangerous.

- Only qualified persons who have passed the appropriate examinations and have such credentials in their possession shall be permitted to use explosive actuated tools. Safety glasses must be worn when explosive actuated tools are used.

- All extension cords must be insulated with a three prong-grounding plug.

- No safety guards installed by the manufacturer shall be removed or blocked.

- Make sure grinding wheels are used within the RPM limit.

- Air lines on pneumatic tools should not be disconnected until pressure is relieved.

- Air line hose connections should be secured to prevent whipping action, should the connection fail under pressure.

- All electrical equipment and tools should be properly grounded.

- All power and hand tools are to be oiled and cleaned on a regular basis.